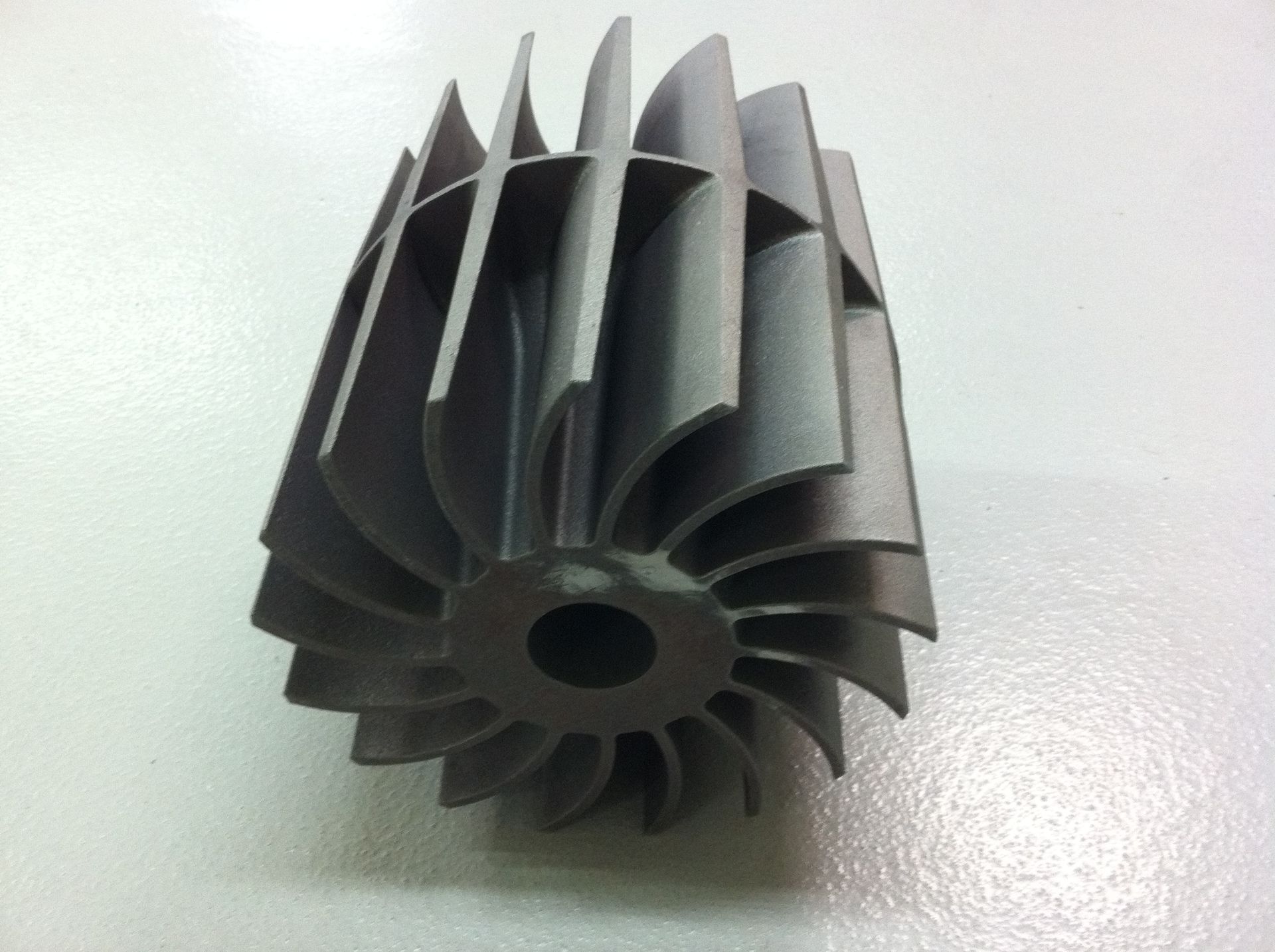

Prototype Ductile Iron Castings

Prototype Ductile Iron Castings are ideal for applications requiring strength, toughness, and fatigue resistance. At CPM Industries, we manage ductile iron casting projects from concept to completion — including pattern tooling, casting, machining, and quality control.

With our in-house pattern and machine shops, we offer faster turnarounds, tighter tolerances, and better cost control. Our foundry partners provide additional flexibility for size, grade, and complexity — ensuring you get the right process for your part.

Whether you need a single prototype or a small production run, we provide complete support — including secondary services like heat treat, coatings, and inspection.

Prototype Ductile Iron Support

| Capability | Detail |

|---|---|

| Pattern Tooling | CNC-Machined Patterns, 3D Printed Sand Molds & Cores |

| Weight Range | Up to 2,000 lbs |

| Quantities | 1 to 100+ parts(ideal for low-volume and prototypes) |

| Services Provided | Tooling, Casting, Machining, Heat Treating, Painting, Coatings, Assembly, Non-Destructive Testing, Inspection, PPAP, FAIR |

| Non-Destructive Testing | Magnetic Particle Inspection, X-Ray, Dye Penetrant, Fluorescent Particle Inspection |

| In-House Capabilities | Pattern Shop and CNC Machine Shop |

| Common Ductile Iron Grades | 60-40-18, 65-45-12, 80-55-06, 100-70-03 |

| Certifications | ISO 9001:2015 |

| Industries Served | Aerospace, Defense, Automotive, Industrial, Marine, Energy |

Why Work With CPM Industries

CPM Industries provides flexible, turnkey casting support — from pattern tooling through machining and inspection. We’re the partner engineers and sourcing teams trust for prototypes, short runs, and projects that require close coordination across multiple processes.

Learn More